Fibre to Fabric NCERT 7th Class CBSE Science Chapter 03

Question: Name the sources of obtaining fibres.

Answer: The sources of obtaining fibres are plants and animals.

Question: Name some wool yielding animals.

Answer: Wool yielding animals are sheep, yak, llama, alpaca, angora goat, angora rabbit and camel.

Question: In which part of India, yak wool is common?

Answer: Yak wool is common in the hilly regions of Ladakh.

Question: Rampur bushair and Bakharwal are the breeds of which animal-sheep or goat?

Answer: Rampur bushair and Bakharwal are the breeds of sheep.

Question: How do the hair of certain animals help in keeping their bodies warm?

Answer: Hair traps a lot of air which is a poor conductor of heat resulting their body warm.

Question: Write the name of the animal from which wool for pashmina shawls is obtained.

Answer: Kashmiri goats.

Fibre to Fabric NCERT – Question: Name the goats which are found in Tibet and Ladakh.

Answer: In Tibet and Ladakh, angora goats are found.

Question: Wool is obtained from which body part of sheep?

Answer: Wool is obtained from the fleece or hair of sheep.

Question: Name the natural fibre obtained from insects.

Answer: Silk.

Question: In which part, the wool yielding animals llama and alpaca are found?

Answer: Llama and alpaca are found in South America.

Question: For what purpose, rearing of sheep is done?

Answer: The main aim to rear the sheep is to obtain wool.

Question: What term is used for the following process? Washing of sheep’s fleece to remove dust, dirt, dried sweat and grease.

Answer: Scouring.

Question: Out of scouring or shearing, which process comes first in the production of wool from sheep?

Answer: The first step is shearing then scouring.

Question: To which class, animal fibre or plant fibre, artificial silk belongs to?

Answer: Artificial silk is a plant fibre.

Question: Two fibres are made up of proteins. Name them.

Answer: Silk and wool are two fibres which are made up of proteins.

Question: Name the process of taking out silk fibres from the cocoon for use as silk.

Answer: The process of taking out threads from the cocoons for use as silk is called reeling the silk.

Question: Name the stage next to caterpillar in the life cycle of silk moth.

Answer: The stage next to caterpillar in the life cycle of silk moth is called pupa.

Question: Which stage in the life cycle of silk moth is called cocoon?

Answer:

The covering of silk fibres inside which the caterpillar covers itself is called cocoon.

Question: Write the maximum length of continuous silk thread that can be obtained from a cocoon.

Answer: The maximum length of continuous silk thread that can be obtained from a cocoon is more than that of 1000 feet (1000 to 1500 feet) continuous in length.

Fibre to Fabric NCERT – Question: Define the term ‘selective breeding’.

Answer: The process of breeding of selective parents for obtaining special characters in their offspring such as soft under hair in sheep, is termed as selective breeding.

Question: Silk fibre belongs to which class of organic substance?

Answer: Protein.

Fibre to Fabric NCERT – Question: In the life history of silk moth as

Egg ➝ Larva (or caterpillar) ➝ Pupa ➝ Silk moth which actually makes the silk fibre?

Answer: The larva (or caterpillar) of a silk moth makes the silk fibre.

Questions Short Answer Type

Question: Sheep are herbivores, so which type of feed (or food) is provided by shepherds?

Answer: Sheep are herbivores, and prefer grass and leaves of various trees. Their food also contain a mixture of pulses, corn, jowar, oil cakes (material left after taking out oil from seeds) and minerals.

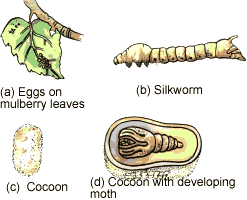

Question: Write a caption for each of the figures given as figure (a-d).

Answer:

(a) Eggs of silk moth on mulberry leaves

(b) Silkworm

(c) Cocoon

(d) Cocoon with developing moth

Question: Silk yarn of different textures can be prepared. Define the statement.

Answer: The silk yarn is obtained from the cocoon of the silk moth. There is a variety of silk moths which look very different from one another and the silk yarn they yield is different in textures (coarse, smooth, shiny, etc.) Thus, tassar silk, mooga silk, kosa silk, etc are obtained from cocoons spun by different types of moths.

Question: Write the difference between natural silk and artificial silk.

Answer: Natural silk is obtained from the cocoons of silkworms and it is made up of a protein. Natural silk is an animal fibre. Artificial silk is obtained from wood pulp and it is made up of modified plant material ‘cellulose’.

If we perform the burning test, then natural silk fibre burns giving a smell of burning hair while artificial fibre burns giving a smell of burning paper.

Fibre to Fabric NCERT – Question: Sorter’s disease is an occupational hazard. Explain.

Answer: Wool industry is an important source of livelihood for many people in our country. The people who do the job of sorting (separating) the fleece of sheep into fibres of different qualities are called sorters. The sorter’s job is very risky because sometimes, they get infected by the bacteria called ‘anthrax’ which cause a deadly blood disease called sorter’s disease.

Question: Write a short note on how first silk industry began in China.

Answer: According to an old Chinese legend, the empress Si-lung-Chi was asked by the emperor Huang-ti to find the cause of the damaged leaves of mulberry trees growing in their garden. The empress found white worms eating up mulberry leaves. She also noticed that they were spinning shiny cocoons around them.

Accidentally, a cocoon dropped into her cup of tea and a tangle of delicate threads separated from the cocoon. This is how silk was discovered by chance. In this way, the first silk industry began in China.

Question: Various steps involved to obtain wool from fleece are given here.

- Picking out the burrs

- Dyeing in various colors

- Shearing

- Scouring

- Sorting

Fibre to Fabric NCERT – Question: Write the above steps in the correct sequence in which they are carried out.

Answer:

Correct sequence is

(iii) Shearing

↓

(iv) Scouring

↓

(v) Sorting

↓

(i) Picking out the burrs

↓

(ii) Dyeing in various colors

Question: Steps for the production of silk are given below in a jumbled order. Arrange them in their proper sequence.

(a) Eggs are warmed to a suitable temperature for the larvae to hatch from eggs.

(b) Fibres are taken out from the cocoon.

(c) After 25 to 30 days, the caterpillars stop eating and start spinning cocoons.

(d) The larvae/caterpillars or silkworms are kept in clean trays along with freshly chopped mulberry leaves.

(e) Female silk moths lay eggs.

(f) Cocoons are kept under the sun or boiled in water.

Answer: The correct order is

(e) Female silk moths lay eggs.

(a) Eggs are warmed to a suitable temperature for the larvae to hatch from eggs.

(d) The larvae/caterpillars or silkworms are kept in clean trays along with freshly chopped mulberry leaves.

(c) After 25 to 30 days, the caterpillars stop N eating and start spinning cocoons.

(f) Cocoons are kept under the sun or boiled in water.

(g) Fibres are taken out from the cocoon.

Fibre to Fabric NCERT – Question: Cocoon is used to obtain silk thread. How?

Answer: A pile of cocoon is used for obtaining silk fibre. The cocoon are kept under the sun, boiled water or exposed to steam.

The silk fibres separate out. The process of taking out threads from the cocoon for use as silk is called reeling the silk.

Question: Name different types of silk. Which variety of silk is most common and how it is obtained?

Answer: Different types of silk are mulberry silk, tassar silk, mooga silk and kosa silk. The most common variety of silk is mulberry silk. It is obtained from the cocoons of mulberry silkworm and is made up of protein. It is a natural silk and is an animal fibre.

Question: Four different types of fibres are given to us. Out of these, two fibres (1 and 2) are obtained from plants and other two (3 and 4) fibres are obtained from animals. Fibre (1) is used in filling quilts and the yarn made of fibre (2) is used in making gunny bags, The yarn made from fibre (3) is used for knitting sweaters and yarn of fibre (4) is used for weaving saries. Name the four given fibres marked 1,2, 3 and 4.

Answer: Fibre (marked 1) which is used in filling quilts is cotton and fibre (marked 2) is jute. (cotton and jute are plant fibres).

Fibre (marked 3) is wool and fibre (marked 4) which is used for weaving saris is silk. (wool and silk are animal fibres).

Fibre to Fabric NCERT – Question: Why caterpillars need to shed their skin when they grow bigger but humans do not? Do you have any idea?

Answer: The caterpillar eats day and night the leaves of mulberry tree and grows big in size whereas its skin does not increase in size, shape or length. During the feeding period, a silkworm sleeps four times (24 h each time) at intervals of six days.

While sleeping, its skin cracks and on awakening, the worm leaves the old skin and comes out in a new one. So, it sheds skin and this phenomenon is called moulting. After the final moulting begins, the last feeding period (of about ten days) after which the worm grows to its full size.

Question: Radhika wanted to buy a silk frock and went to the market with her mother. There they found that the artificial (synthetic) silk was much cheaper and wanted to know why? Do you know why? Find out.

Answer:

Artificial (synthetic) silk called rayon is obtained from wood pulp and it is made of modified plant material cellulose. Synthetic silk can be prepared at a large scale in factories / mills. So, it is cheap. For obtaining pure silk, we have to rear silk moth, their larvae to get pupa.

To get silk thread, we have to dip cocoon in hot water to get silk thread which is wrapped over the cocoon. The pupa inside the cocoon dies. To obtain silk for commercial purposes, a large number of cocoons (containing living pupa) are killed. As a result, natural silk is costly.

Question: From what type of health problems the workers suffered while working in a wool industry?

Answer:

People working in the wool industry sometimes get infected by a bacterium called anthrax, during the sorting (separating) the fleece of sheep into fibres of different qualities.

It leads to a fatal blood disease called sorter’s disease.

Fibre to Fabric NCERT – Question: Write the different types of fibres that form the hair of sheep.

Answer:

There are following two types of fibres that form the hair to sheep

- The coarse beard hair.

- Fine soft under hair close to the skin.

Question: Name the most common silk moth. What are the characteristics of silk fibres obtained from the cocoons of this silk moth?

Answer: The most common silk moth is the mulberry silk moth. The silk obtained from the cocoons of mulberry silk moth is called mulberry silk. Mulberry silk is soft, lustrous (shiny) and elastic and can be dyed in different colors.

Question: Paheli went to the market to buy sarees for her mother. She took out a thread from the edge of the two sarees shown by the shopkeeper and burnt them. One thread burnt with a smell of burning hair and the other burnt with the smell of burning paper. Which thread is from a pure cotton saree and which one from a pure silk saree? Give reason for your answer.

Answer: In first saree, one thread which burnt with a smell of burning hair is from pure silk, silk and hair are protein fibres. So, on burning these threads, a smell of burning hair comes out. In second saree, second thread which burnt with the smell of burning cotton and paper because cotton and paper both are carbohydrates and on burning they give similar smell.

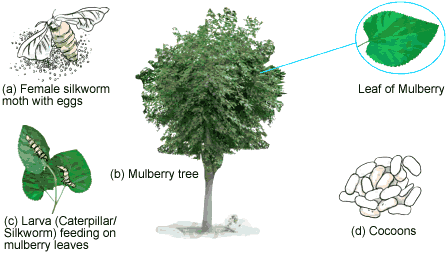

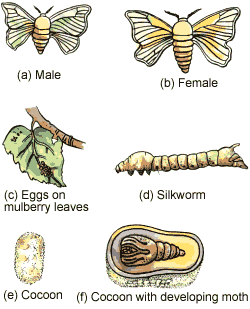

Question: Describe the life history of silk moth with the help of figures of various stages.

Answer: Life History of Silk Moth Formation of Silkworm

The female silk moth lays eggs on mulberry leaves. The eggs are hatched into very small larvae within a week. The larvae of silk moth are called caterpillar or silkworm. The silkworms feed on the leaves of mulberry tree and grow bigger in size.

(a to f) Life history of silk moth

When the silkworm (or caterpillar) is ready to enter the next stage of its development called pupa, it first weaves a net to hold itself. Then, it swings its head from side to side. During these movement of head, the silkworm secrets fibre made of protein which hardens on exposure to air and becomes silk fibre (or silk thread). Soon the silkworm (or caterpillar) covers itself by silk fibres and turns into pupa. This covering is known as cocoon. The silkworm continues to develop in the form of pupa inside the cocoon to form the silk moth.

Production of Silk

In order to produce silk, the silkworm developing inside the cocoon (as pupa) is not allowed to mature into an adult silk moth. So, as soon as the cocoon is formed, it is used to obtain silk fibres and the developing silkworm (as pupa) gets killed. Some of the silkworms (as pupae) are however, allowed to live and mature into silk moths so that they can lay eggs to produce more silkworms.

There is a variety of silk moths which look very different from one another and the silk yarn they yield is different in texture (coarse, smooth, shiny, etc). Thus, tassar silk, kosa silk, mooga silk, etc are obtained from cocoons spun by different types of moths. The most common silk moth is the mulberry silk moth. The silk obtained from the cocoons of mulberry silk moth is called mulberry silk. Mulberry silk is soft, lustrous (shiny) and elastic and can be dyed in beautiful colors.

Take a thread of pure silk and another thread of an artificial (synthetic) silk. Burn them separately and observe the smell produced. The thread which burns giving a smell of burning hair will be pure silk thread. The thread which burns giving a smell of burning paper will be artificial silk thread.

Fibre to Fabric NCERT – Question: How silkworms are reared? Explain in brief.

Answer: Pure and Artificial Silk

Pure silk is obtained from the cocoons of silkworm and it is made up of protein. Artificial silk is obtained from wood pulp and it is made of modified plant material ‘cellulose’. Just like silk, wool is also made up of proteins. So, a piece of woollen fabric also burns giving the smell of burning hair. The thread which burns giving a smell of burning paper will be cotton fibres. Cotton and paper both are carbohydrates. Paper is made of cellulose obtained from wood pulp. So, on burning cotton and paper both give similar smell.

For obtaining silk, silk moths are reared and their cocoons are collected to get silk thread.

Rearing Silkworms

A female silk moth lays hundred of eggs at a time. The eggs are stored carefully on strips of paper or cloth and sold to silkworm farmers. The farmers keep eggs under hygienic condition. They warm them to a suitable temperature for the larvae to hatch from egg.

The larvae are kept in clean bamboo trays along with young and freshly chopped mulberry leaves. After 25-30 days, the silkworms stop eating and start spinning the cocoons. Small racks or twigs may be provided in the trays to which cocoons get attached.

Processing Silk

The cocoons are collected and boiled in water to kill the insect inside them. The resulting fibre is known as raw silk. The silk fibres separate out.

Reeling the Silk

The process of taking out fibres from the cocoon for use as silk is known as reeling the silk. Reeling is done in special machines. Silk fibres are spun into silk threads which are woven into silk cloth by weavers.

Question: Explain the phrase – ‘Unity is Strength’ on the basis of the making of fabric from fibre.

Answer: Fibres and fabric play a large role in everyday applications. A fibre is a hair-like strand of material. They are the smallest visible unit of a fabric and denoted by being extremely long in relation to their width. Fibres can be spun into yarn and made into fabric. A single fibre is too weak to break but when it once made a fabric it is difficult to tear. Fabric needs more energy to tear apart as compared to a single fibre.

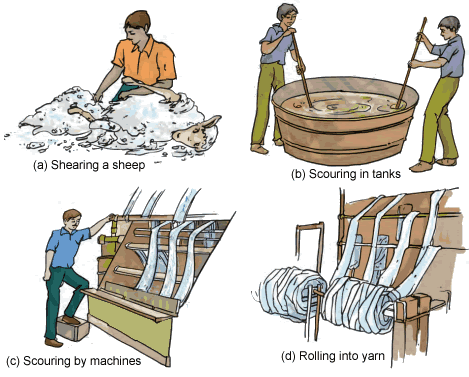

Fibre to Fabric NCERT – Question: Write various steps for processing fibres into wool.

Answer: Processing of Fibres into Wool

The wool which is used for knitting sweaters or for weaving shawls is the finished product of a long process. Processing of fibres into wool involves the following steps:

Step I

The fleece of the sheep along with thin layer of skin is removed from the body. This process is called shearing. The hair of the sheep are shaved off by using a saving machine similar to that used by barbers.

Shearing does not hurt the sheep because the uppermost layer of the skin of sheep is ‘dead’. The shearing (cutting the hair) of sheep is done in hot weather of summer so that sheep may survive without their protective coat of hair. The hair of sheep grow again before the onset of winter and protect them in cold weather. The fleece (or hair) of sheep provides woolen fibres. Woolen fibres are then processed to obtained woolen yarn.

Step II

The fleece of sheep (or cut hair of sheep) contains dust, dirt, dried sweat and grease, etc. So, the sheared hair of sheep are thoroughly cleaned by washing with soap (or detergent) and a lot of water in tanks. This process of washing of sheared hair is called scouring. Scouring makes the fleece of sheep clean. The scoured fleece is then dried. Now-a-days scouring is done by machines.

Step III

After scouring, sorting is done. The process of separating the fleece of a sheep into sections according to the quality of woolen fibres (such as fine, coarse, long, short, etc) is called sorting. In sorting, the hairy skin is sent to a factory where hair of different textures are separated or sorted. Every section of wool obtained after sorting contains the same quality wool. The same quality wool obtained are then mixed together.

Step IV

The small fluffy fibres, called burrs, are picked out from the hair (burrs are soft, fluffy fibres in wool).

(After this, the fibres are scoured again and dried. The wool obtained after this is ready to be drawn into fibres).

Step V

The natural fleece or hair of sheep (or goat) is white, brown or black in colour. The white woolen fibre obtained by sorting can be dyed in different colors.

Step VI

The fibres are straightened, combed and rolled into yarn. The long woolen fibres are spun (or twisted) into thick yarn called wool which is used for knitting sweaters, etc.

The short woolen fibres are spun into fine yarn and then woven on a loom to make woolen clothes (like shawls, etc).

Finally, we conclude that the sheep’s hair is sheared off from the body, scoured, sorted, dyed, combed and spun to obtain wool (for knitting sweaters) and woolen yarn (for weaving cloth). The quality of woolen cloth depends on the breed of sheep from which wool is obtained.

Processing fibres into wool

Question: Neha went to the market with her mother to buy a silk saree for her grandmother. The shopkeeper was showing sarees of different varieties of silk but her mother wanted to take only a pure silk saree and not an artificial one. Neha was confused that how to distinguish between a pure silk and an artificial silk saree. But her mother helped her in selecting a pure silk saree for her grandmother and she was quite elated about that.

Now, answer the following questions:

- How her mother distinguished between pure silk saree and an artificial silk saree?

- Is the pure silk saree more costly than an artificial one?

- What values are shown by Neha’s mother?

Answer:

- Neha’s mother took a thread of natural silk fabric and another thread of artificial silk fabric and burn them separately. The thread which burns giving a smell of burning hair will be natural silk (or pure silk). The thread which burns giving a smell a burning paper will be an artificial silk.

- Yes, pure silk saree is more costly than an artificial one.

- Neha’s mother is intelligent and knowledgeable.

Question: Ajay’s father works in a wool industry. In his line of work, he does the job of sorting the fleece of sheep into fibres of different qualities. Ajay noticed that his father and other workers who were doing the similar kind of jobs faced a number of health problems.

Ajay discussed this problem with his friends and he came to know that his father is getting health problems due to the nature of his work.

Ajay is worried about his father’s health. He advised his father to take care of their health and told him about the occupational hazards.

Now answer the following questions.

- What do you mean by occupational hazard?

- Name the disease that workers may at risk.

- What values are shown by Ajay?

Answer:

- The risks faced by people working in any industry due to the nature of their work are called occupational hazards.

- The people who do the job of sorting, sometimes, get infected by the bacteria called anthrax which cause a deadly blood disease called sorter’s disease.

- Ajay is very caring, intelligent and sensible boy.

Question: Name some breeds of sheep reared in our country. Explain the quality of wool they provide and the state where they are found.

Answer:

| Name of breed of sheep | Quality of wool | Name of the state where found |

| Lohi | Good quality wool | Rajasthan, Punjab |

| Rampur bushair | Brown fleece | Uttar Pradesh, Himachal Pradesh |

| Nali | Carpet wool | Rajasthan, Haryana, Punjab |

| Bakharwal | For woolen shawls | Jammu and Kashmir |

| Marwari | Coarse wool | Gujarat |

| Patanwadi | For hosiery | Gujarat |

Class Notes NCERT Solutions for CBSE Students

Class Notes NCERT Solutions for CBSE Students